Common causes of fuel injector failures and how to avoid them

The modern diesel engine is a highly complex system of components that work in unison to create the efficient power that drives our industries. The technology that kicked off this modern diesel revolution is the common rail fuel system, coupled with an electronic control unit. Common rail fuel systems entered the U.S. market in 2001. They were a massive shift from traditional fuel systems, such as inline pumps and distributor pumps, making all of the old associations with loud diesel engines a thing of the past.

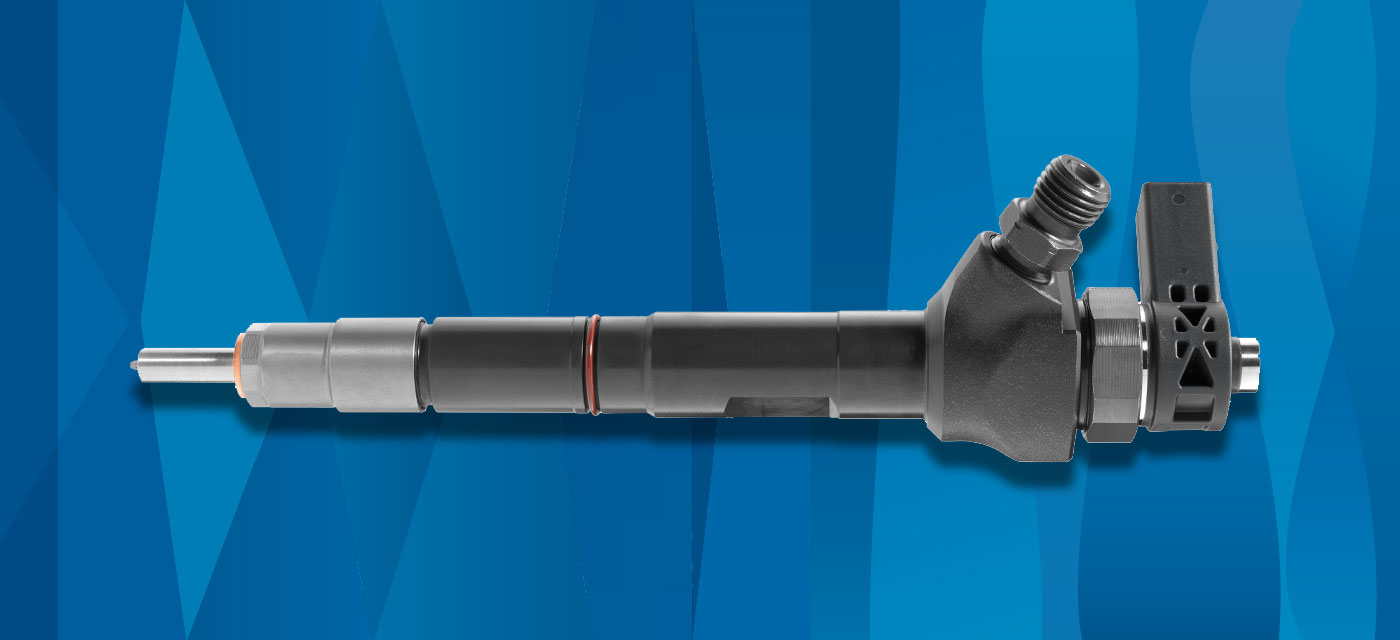

At the heart of these new systems were solenoid actuated fuel injectors operating at over 23,000 psi and capable of injecting multiple times per cylinder stroke. Today, it’s not uncommon to find these original vehicles on the road with over 300,000 miles, still working hard for their owners. Naturally, these vehicles do need servicing to continue working properly and a commonly replaced component is the fuel injector.

In the first few years of common rail, the service options were limited. OEM’s offered new injectors and gradually began offering remanufactured solutions. With access to both the OE test equipment and the low tolerance component parts, these reman solutions were a high-quality cost-effective repair alternative.

Within the last decade, however, there's been an influx of third-parties manufacturing injectors. And with this rise of third-parties came an increase in injector problems.

To explore these issues further, Bosch recently conducted a study on a broad sample of rebuilt or remanufactured common rail fuel injectors. We ran them through production test equipment and then took them apart to see the different components used.

What we found was concerning

More than half of the parts we tested failed to operate according to OE test points, and they represented a significant hazard to the engine if installed. Many contained reused elements that were unacceptably ground down or rusted. As well as new, non-OE components that prevented the injector from operating properly. When installed on the vehicle common symptoms included exhaust system damage, unusual engine noises, smoke, and power loss, We also saw fuel mileage decrease in the 5-10 percent range.

With various remanufactured injector options on the market, it's vital that service technicians can trust the part they are installing on the vehicle.

Common causes of injector failure

Modern common rail systems generally have a long lifespan. However, they're still susceptible to issues. While many things can cause breakdowns, the most likely cause of premature failure is fuel contamination. Fuel contamination occurs when debris in the fuel gets past the filtration, destroying the sealing surfaces. Think microns, smaller than a human's hair-sized, clearances. Any debris passing through acts like sandpaper and wears down a groove in key sealing surfaces until they no longer function properly.

The second most common issue is water in the fuel. Since everything is metal inside, water causes corrosion. This can either cause debris in the system or close the micron level clearance between parts, leading to sticking.

Lastly, you'll want to be wary of incorrect installations, which is especially important to look out for if your customers are coming from different shops. Look out for missing sealing rings, improper tightening torque, and inadequate cleaning of the nozzle. These can cause performance issues, misfiring, black smoke, and the appearance of the check engine light.

What to look for in an injector

First and foremost, you need to have access to the scan tools and OE procedures to diagnose fuel injector issues accurately. The Bosch Diesel network features independently owned shops of diesel experts around the country that have the experience and training to diagnose these engines. Misdiagnosis can add money and frustration to an already costly repair. Now that your vehicle has been properly diagnosed, and it is indeed the fuel injectors that need replacement, you have a few options.

The same Bosch Diesel network also offers locations that can test and repair your injectors. These locations are denoted as Bosch Diesel Centers. By testing the injectors and replacing only the components which show signs of wear, it can result in cost savings versus a similar remanufactured injector.

Remanufactured injectors are the most common service solution. However, as covered earlier, not all reman parts are created equal. All remanufacturers are faced with the same decision during the rebuild process. Do I reuse or replace this component? OEM’s will often replace a higher percent of the components because they have access to these parts right off the assembly line. This results in a higher quality finished good. In addition, it has also been flow-tested on production test equipment which guarantees that it meets the specification of that original injector. The last thing you want to do is spend a few thousand dollars and have to question whether that part is working straight out of the box.

Quite often, when you're dealing with a third party, they'll advertise price points a lot lower than OEMs. They can do this by reusing most parts or even testing and reselling used injectors, called core. As we found earlier, more than half of these injectors fail standard testing procedures. Time is money, and some injector jobs are upwards of 8-10 hours of labor. That's all wasted if you can't trust the product.